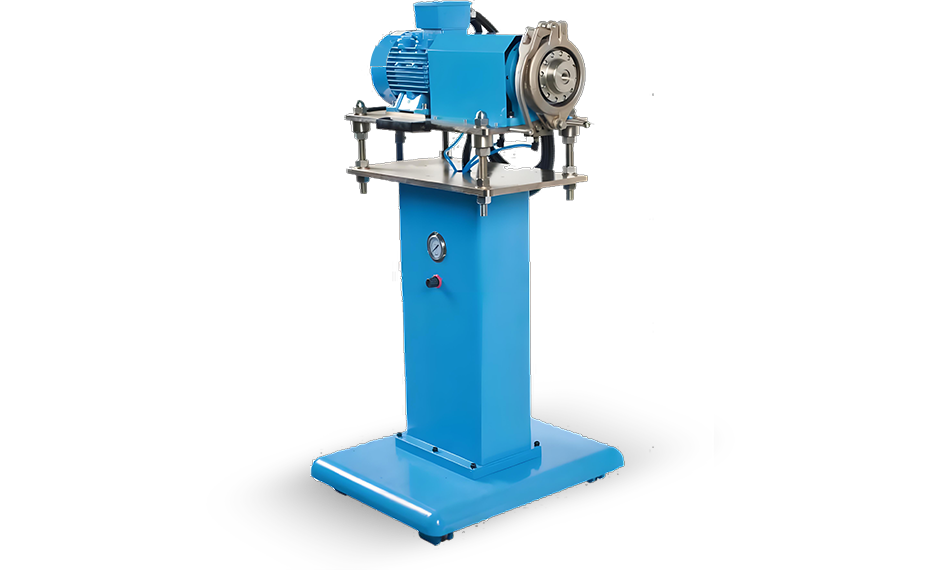

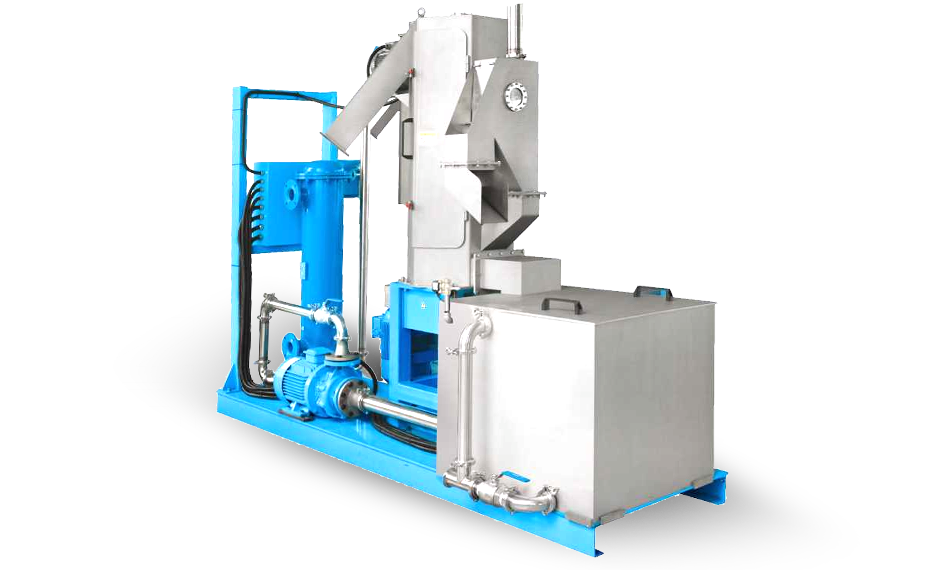

Materials can be processed by Underwater Pelletizing Systems:

Hot melt adhesives, Polyurethane (TPU), Polyoxymethylene (POM), Polyester (PET), Resins (synthetic & natural), Elastomers (TPE, TPV), Polyolefins (PE, PP, POE), Polyamides (PA6, PA11, PA12), Polystyrene (ABS, SAN, PS), Micro pellet materials (PE, PP, PS, EPS), Biodegradable plastics (PLA, PBS), Color masterbatch, and more.

Plastics & Engineering Plastics

Commodity Plastics: Polyolefin (PP, PE) pellets, suitable for injection molding, blow molding, and extrusion processes.

Engineering Plastics: Polyamides (PA), Polyesters (PET), Polyoxymethylene (POM), etc., widely used in automotive, electronics, and home appliances.

Engineering Plastics: Polyamides (PA), Polyesters (PET), Polyoxymethylene (POM), etc., widely used in automotive, electronics, and home appliances.

Chemical & Composite Materials

Reinforced Plastics: Carbon fiber (CFRP), glass fiber (GFRP), and mineral-filled plastics.

Functional Plastics: Modified materials with flame retardancy, UV resistance, conductivity, and other specialized properties.

Functional Plastics: Modified materials with flame retardancy, UV resistance, conductivity, and other specialized properties.

Special Material Applications

High-Performance Materials: Medical or special plastics suitable for high-viscosity and heat-sensitive processes.

Functional Masterbatch: Color masterbatch, antibacterial masterbatch, and other additives that impart specific properties to plastics.

Food & Medical Plastics: High-purity PP, PET for food packaging; PVC and silicone rubber for medical devices.

Functional Masterbatch: Color masterbatch, antibacterial masterbatch, and other additives that impart specific properties to plastics.

Food & Medical Plastics: High-purity PP, PET for food packaging; PVC and silicone rubber for medical devices.

Recycled & Eco-Friendly Plastics

Recycled Plastics: Processing of post-consumer or post-industrial plastics (e.g., PET bottles, HDPE containers) into regenerated pellets.

Biodegradable Plastics: Materials such as PLA, used for eco-friendly packaging and disposable products.

Biodegradable Plastics: Materials such as PLA, used for eco-friendly packaging and disposable products.

Keep exploring Pelletizing Technology

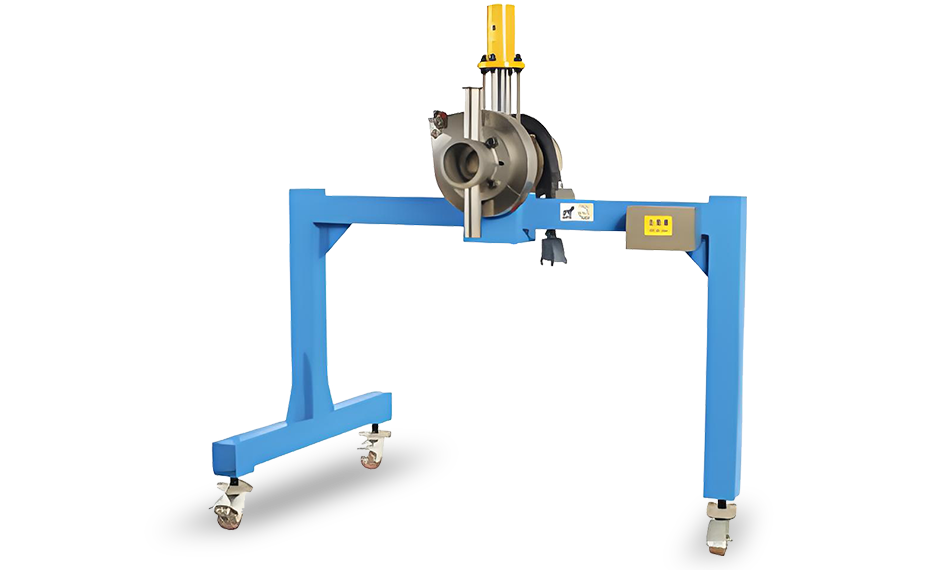

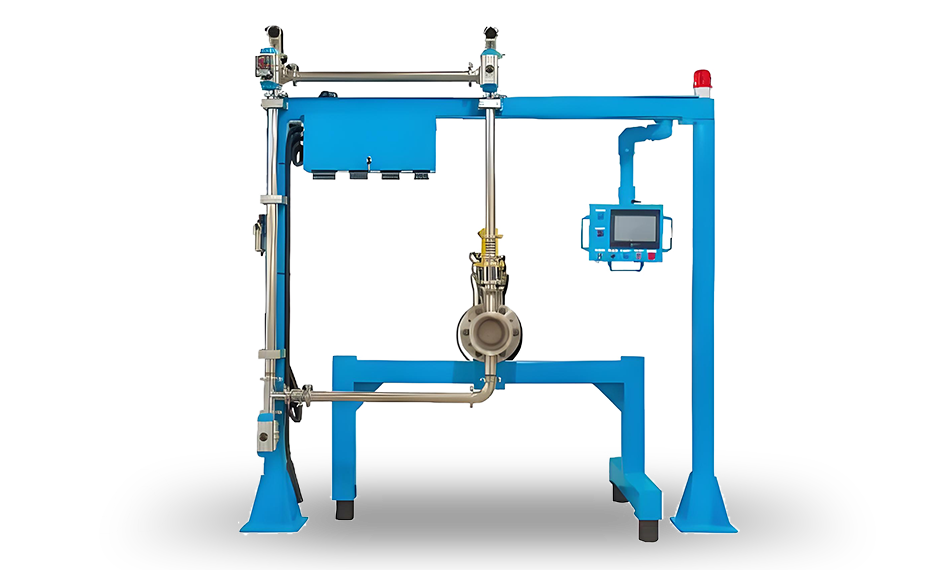

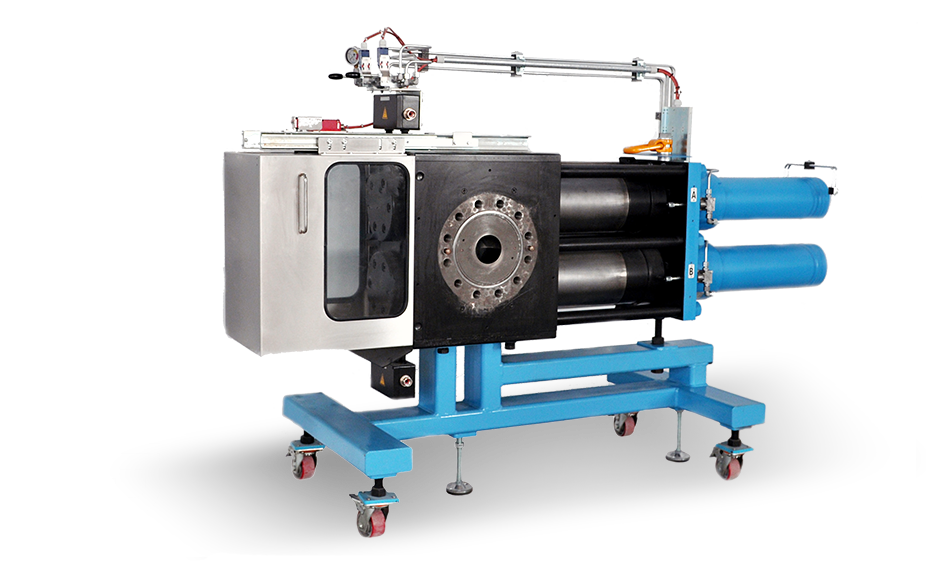

With the development of polymer processing, pelletizing process is becoming more efficient, more intelligent, more stable.Underwater pelletizing offers continuous operation, rapid cooling, and uniform spherical pellets, making it a key process for high-quality production with excellent downstream efficiency and adaptability.

100+ Strong Partners, Delivering Excellent Service

Rongpai has established deep collaborations with leading global companies, continuously integrating advanced technologies and management practices. This robust international network enhances our R&D and service capabilities, providing customers with innovative, high-quality solutions that drive success in the global market.

Partnership with Rongpai

Starts with a Choice, Goes Beyond Products

Starts with a Choice, Goes Beyond Products

At Rongpai, our relationship with every customer goes far beyond product transactions. Choosing Rongpai is just the beginning of a collaborative journey. With years of R&D experience and deep collaboration with polymer manufacturers, we offer comprehensive capabilities across development, production, and service, providing reliable support to build trust, mutual benefits, and sustainable partnerships.