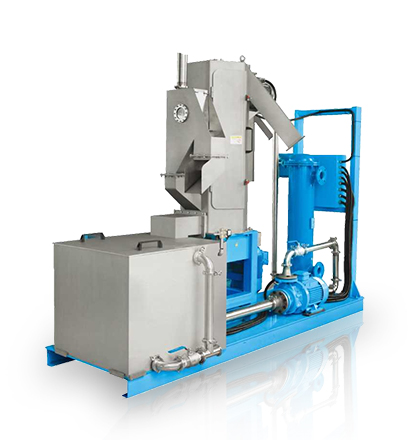

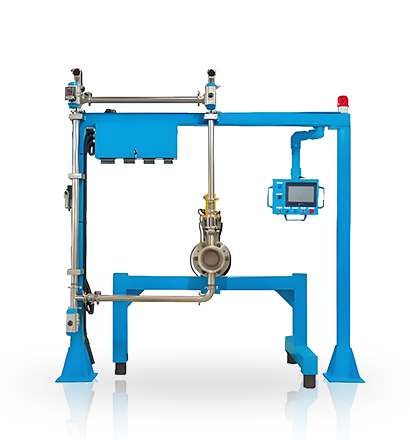

Application

Chemical & Composite Materials

Rongpai underwater pelletizing systems are widely used in the chemical and composite materials industry, processing functional plastics, flame-retardant materials, glass-fiber reinforced plastics, carbon-fiber composites, and various modified plastics.

These materials require precise control of pellet size, uniform distribution, and flowability to meet downstream processes such as injection molding, extrusion, and blow molding. Rongpai underwater pelletizing systems operate stably under high temperature and high viscosity, ensuring high-quality pellets for filled and reinforced composite materials.

The application of underwater pelletizing systems in the chemical and composite materials industry primarily covers filled and modified materials, high-strength reinforced plastics, and functional plastics.