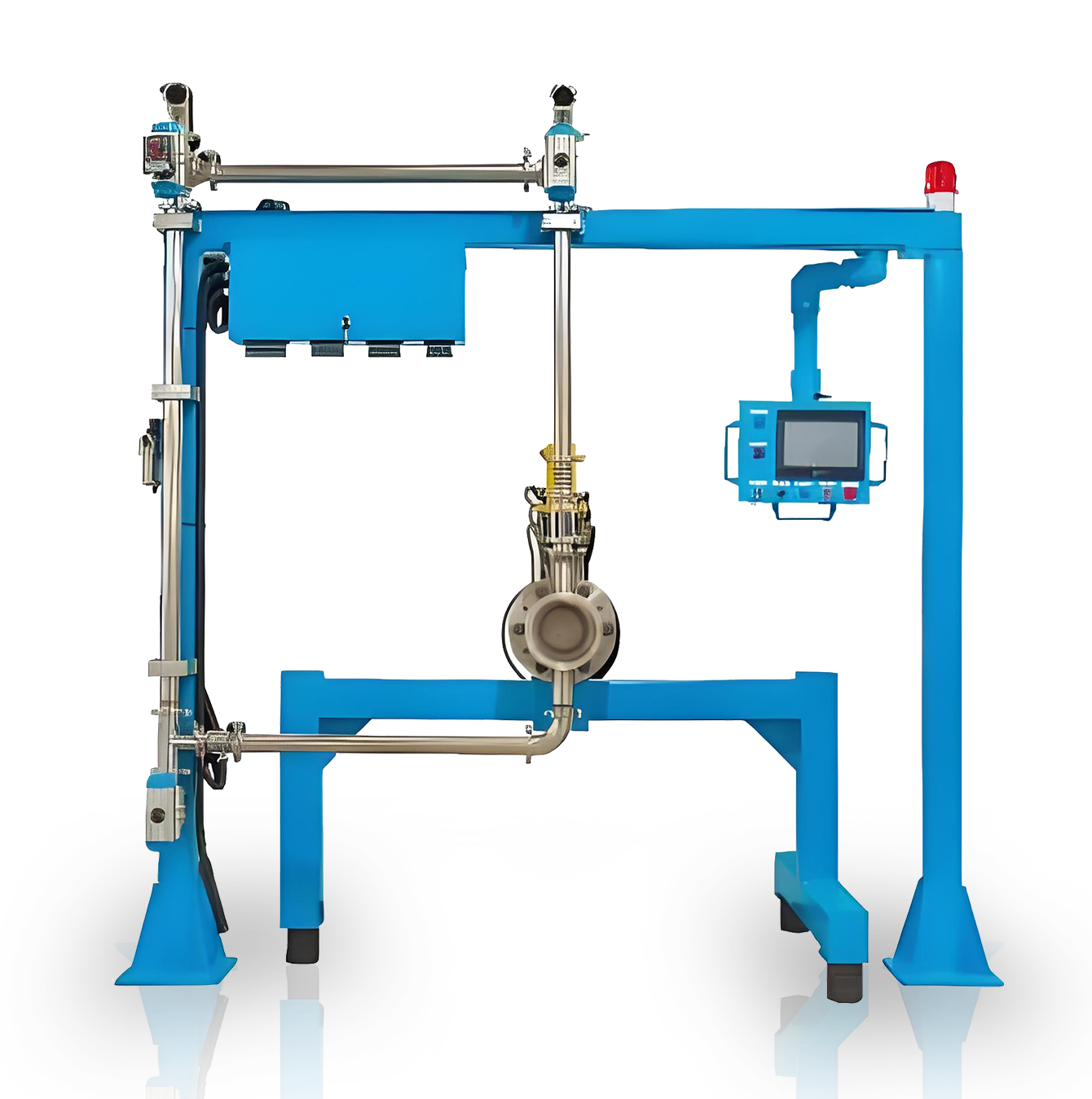

By-pass

Premature or delayed entry of process water into the cutting chamber can lead to unsuccessful startup or even significant production losses in underwater pelletizing operations.

The by-pass system allows precise control of the timing for process water to reach the cutting chamber, maximizing startup success and production efficiency.

By-pass line